Testing Intake Air And Exhaust Systems Mechanical Resistance To Vibration

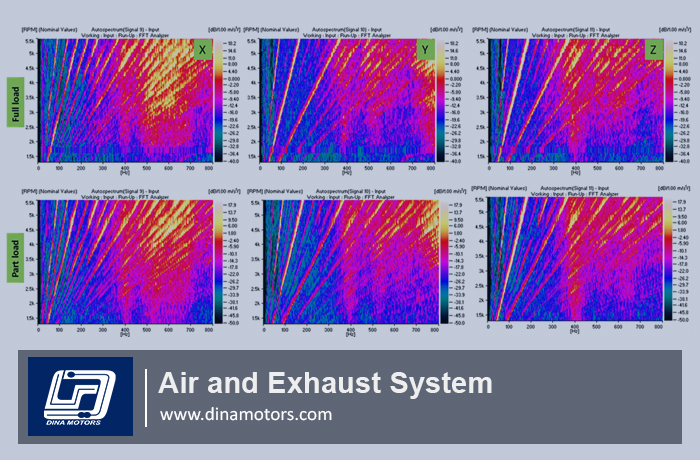

Air and Exhaust systems, due to being connected to an internal combustion engine, are subjected to constant vibrations. As a consequence, these systems suffer cyclic stresses that lead to fatigue cracks. The catalytic converter assembly, in which the ceramic substrate is housed in a metal casing, is particularly susceptible to damage resulting from vibrations. These systems must be validated in terms of their fatigue strength. Durability tests of a specific catalytic converter unit or particulate filter precede vibration measurements. These measurements are performed using tri-axial accelerometers placed in locations considered to be the most exposed to vibrations. Analysis of the results obtained determines the rotational speed of the engine at which vibrations reach critical resonant frequencies. The speed values thus obtained are the basis for determining the test profile to which the exhaust system will be subjected. The duration of the test depends on the required number of displacement cycles which the element under test should be able to withstand. Vibration test’s also can be performed on test bench using an electrodynamic inductor.

.

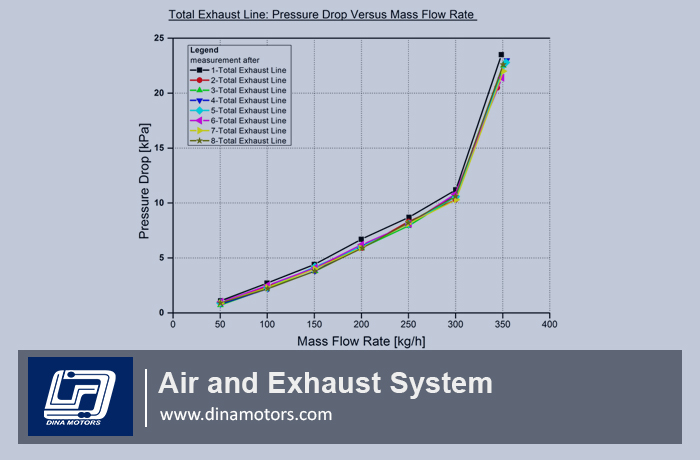

Exhaust Line Measure Headloss And Of The Back-pressure

The test consists in determining the headloss of the element measured according to the gas output which crosses it, and of the conditions of temperature and pressure of this gas. To determine this headloss, one measures the static pressures upstream and in certain cases downstream from the characterized element.

Then, by calculation of the static pressures (according to the pressure and of the temperature of the air), and by making the difference between the values upstream and downstream from the element, one determines his headloss.

The air flow crossing the element is measured by a volumic or voluminal flow-meter, and the static pressures are measured by sensor. If the voluminal air flow is measured, one from of deduced the volumic temperature and air flow starting from the pressure raised during the test. This test can be performed on a engine test bench but DinaMotors has Designed Indevidual test bench to have more repeatable measurement save cost and time.

.

Thermal Shock Tests

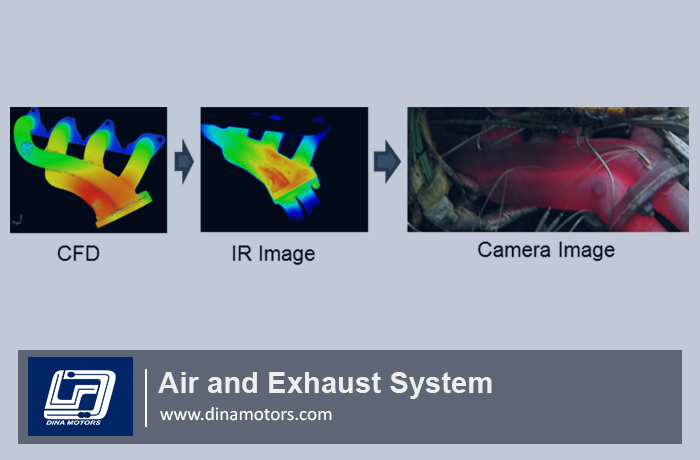

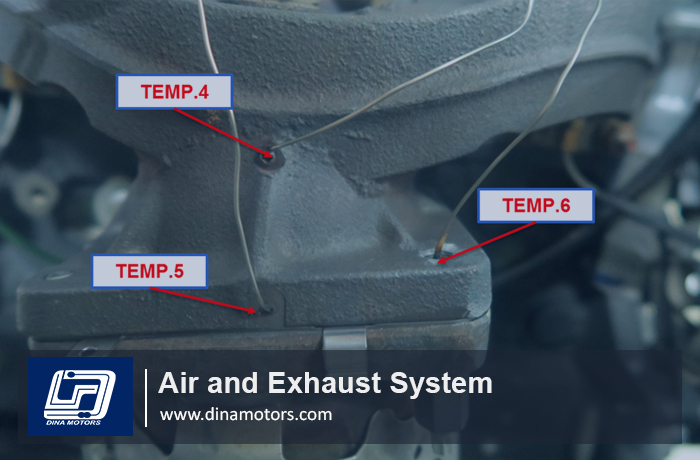

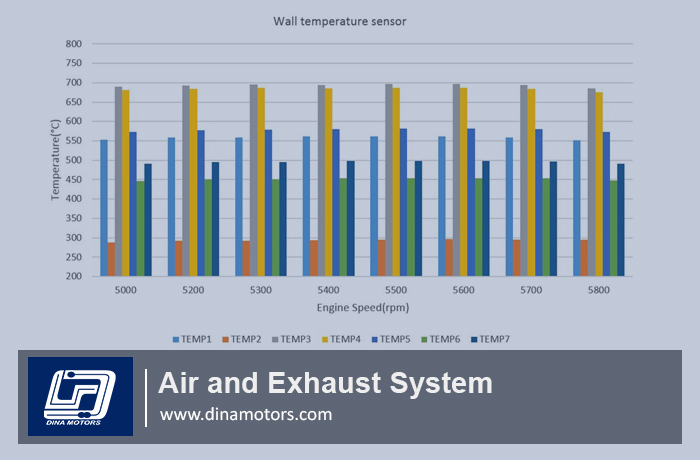

Thermal shock tests are experiments conducted on an engine installed on a dyno, which aim to assess the influence of extreme temperatures on exhaust system components, as well as assessing wear and thermal deformations.

During such tests, temperature of specified points will be measured through 500 hundred thermal cycles in different Engine speed and engine loads. For better analysis we monitor component’s temperature using IR camera and gun.

We also provide CFD services to present solution for better performance.