Special tests include non-standard tests performed using specialist test equipment, such as strain gauges to determine material deformation, or tests performed on a specially prepared test stand (TILT), which are designed to determine the specific parameters of the engine and its components.

.

.

Direct measurements of deformation using strain gauges at temperatures up to 200°C. Measurements in quarter-bridge, semi-bridge and full-bridge systems, with frequency ranges as high as 40 kHz.

Possibility of recording the signal for later analysis. Static, quasi-static and dynamic measurements.

.

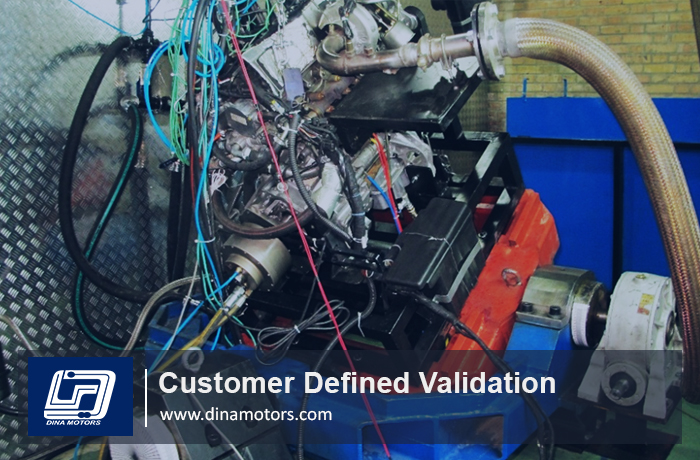

Validation tests of engines run on the engine dyno aim to determine the durability and reliability of the engine, including its individual components. Such tests, depending on the type of engine (light duty/heavy duty), last from 400 to 3000 hours and simulate accumulated mileages in the range of 150000 to 500000 km in a relatively short time. At the test bench, any test can be mapped and performed under reproducible laboratory conditions, which facilitates the interpretation of the results obtained and also lowers the test costs in relation to the work carried out on the vehicle. The engines are equipped with a series of sensors that measure the current operating parameters (e.g. temperature, pressure, ECU parameters) registered by the automation system, and at the end of the test, depending on the customer’s requirements, a detailed metrological and material analysis is carried out allowing a final assessment of each component and possible qualification for production.

.

Environmental testing simulates the different climatic conditions and mechanical stress that products are exposed to during their lifetime. In general, environmental tests demonstrate that your products have the build quality to work perfectly, no matter what the conditions. During testing, possible weaknesses can be identified and product improvements can be initiated at an early stage. Environmental testing also helps demonstrate compliance of your products with international regulations, making it easier to access global markets. Environmental testing also boosts trust in your products.

.

We provide a range of environmental testing services, including:

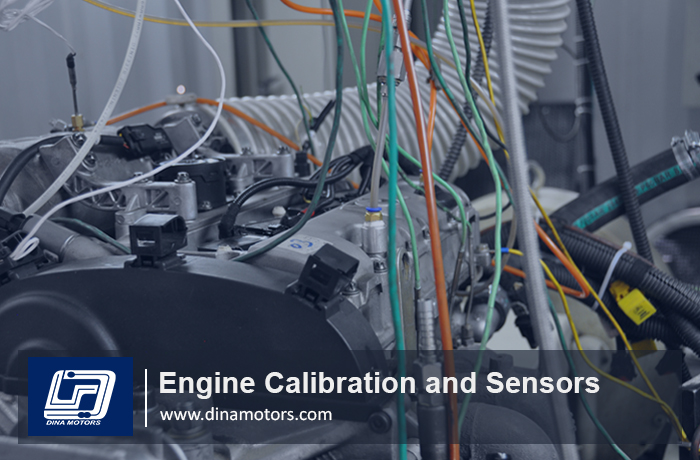

Development tests of engine prototypes conducted on the dyno focus on the selection of individual components and engine systems, their optimization for a given application, verification of technological assumption tests created during the engine design stage on the real object, together with simulation tests. At this stage, engine control unit calibration works are conducted in parallel in order to provide full functionality of engine components.

.

Functionality tests of engine components and systems are conducted on the dyno in order to verify and assess the operational correctness of individual engine subassemblies. The verification is usually based on the result analysis delivered during durability tests conducted on the testing bench, together with assessments of wear of a given component, subjecting it to meteorological and material tests, as well as via visual inspection.

.

Determination of the influence of the fuel in use on engine parameters, efficiency, exhaust emissions, injection system functionality, etc. Tests of injector nozzle clogging, comparisons of fuels and additives (for engine clean-up or higher performance) and durability tests are performed. Depending on the test type, suitable specialist apparatus is used; for example, a fuel consumption meter together with a fuel conditioning system, exhaust analyzers or opacimeters. Engine dynos are equipped with lines supplying the engine with liquid and gaseous fuels. When needed, there is the possibility of combining fuels or additives in order to achieve the desired mixture. Analyses of the chemical composition of fuels, fuel mixtures or sediments formed during the fuel combustion process are performed on site, greatly improve the analysis of results and the testing process.

.

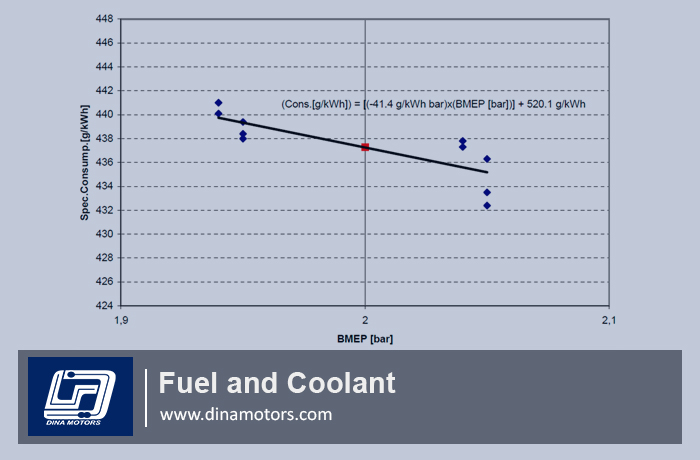

Fuel economy tests are conducted to determine the specific fuel consumption of an engine fuelled with various fuel types, using high precision measuring equipment monitoring fuel consumption which is integrated into the fuel conditioning system (maintaining the fuel temperature and pressure).

.

Comparative tests of the “benchmarking” type are conducted on the engine dyno in order to determine the influence fuel and engine oil produced by different manufacturers on engine parameters. During the test, comparative analyses are conducted based on data such as: engine performance, exhaust emissions, fuel consumption, engine subassembly wear and other defined factors. This type of testing allows evaluation of products available on the market and the selection of fuels or engine oils meeting client requirements.

.

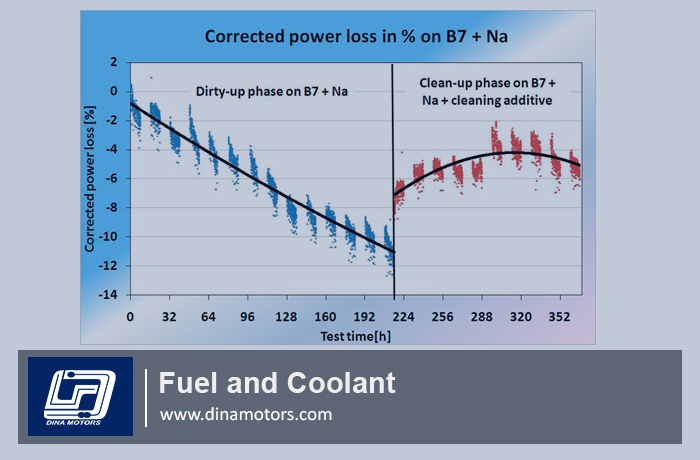

Tests aim to determine the influence of using “dirty” fuel on the formation of sediments and injector nozzle clogging/coking, as well as evaluation of the usage of cleanup additives. Modern engines are equipped with injection systems which require fuels of the highest quality. Due to that fact, tests are conducted on the engine dyno with the aim of specifying the influence of elements like sodium and potassium on the propensity for sediment formation in the injectors’ nozzles at high temperatures, which results in a deterioration of spray formation, a decrease in engine performance and an increase in fuel consumption. Simultaneously, tests of cleanup additives – which decrease the formation of sediments and restore the original engine parameters – are conducted.

.

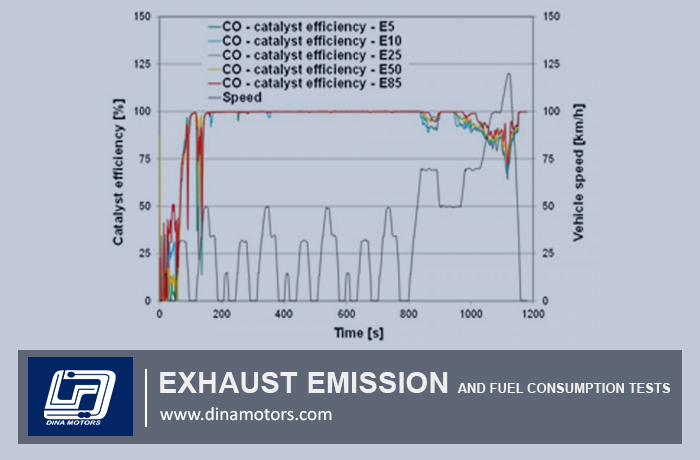

Catalytic reactor (TWC, DOC, NSC, SCR) and solid particle filter (DPF, GPF) efficiency tests

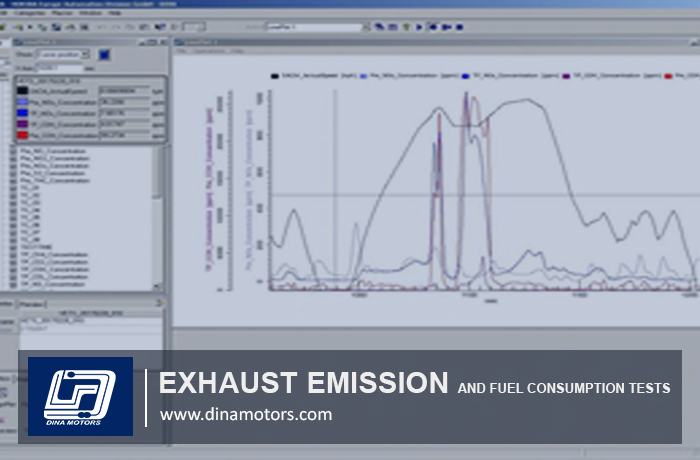

Efficiency tests of catalytic exhaust gas aftertreatment purifying systems through measurements with 2 emission measurement lines of undiluted exhaust before and after the given exhaust aftertreatment system.

Examples of exhaust sampling points:

.

Diluted or undiluted exhaust concentration measurements: CO, CO2, O2, NO, NOx, NO2, THC, CH4

Diluted or undiluted calculations: CO, CO2, O2, NO, NOx, NO2, THC, CH4

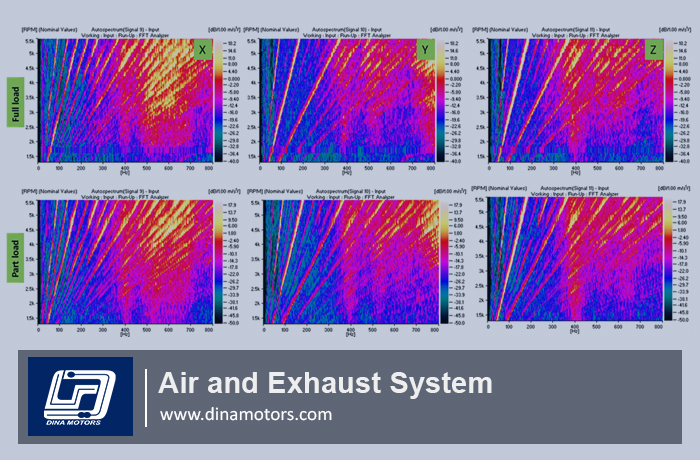

Air and Exhaust systems, due to being connected to an internal combustion engine, are subjected to constant vibrations. As a consequence, these systems suffer cyclic stresses that lead to fatigue cracks. The catalytic converter assembly, in which the ceramic substrate is housed in a metal casing, is particularly susceptible to damage resulting from vibrations. These systems must be validated in terms of their fatigue strength. Durability tests of a specific catalytic converter unit or particulate filter precede vibration measurements. These measurements are performed using tri-axial accelerometers placed in locations considered to be the most exposed to vibrations. Analysis of the results obtained determines the rotational speed of the engine at which vibrations reach critical resonant frequencies. The speed values thus obtained are the basis for determining the test profile to which the exhaust system will be subjected. The duration of the test depends on the required number of displacement cycles which the element under test should be able to withstand. Vibration test’s also can be performed on test bench using an electrodynamic inductor.

.

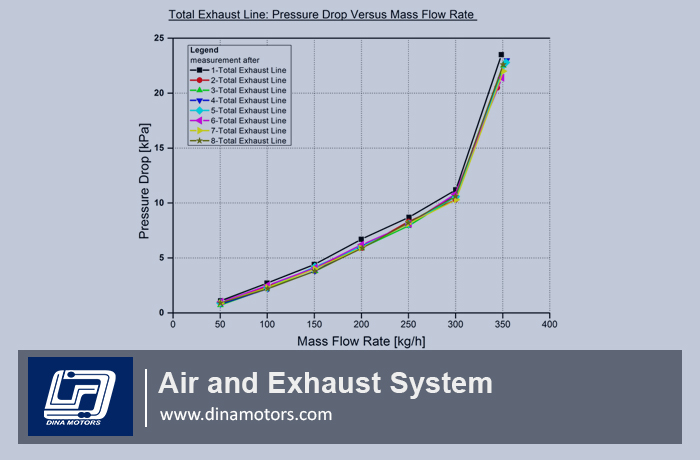

The test consists in determining the headloss of the element measured according to the gas output which crosses it, and of the conditions of temperature and pressure of this gas. To determine this headloss, one measures the static pressures upstream and in certain cases downstream from the characterized element.

Then, by calculation of the static pressures (according to the pressure and of the temperature of the air), and by making the difference between the values upstream and downstream from the element, one determines his headloss.

The air flow crossing the element is measured by a volumic or voluminal flow-meter, and the static pressures are measured by sensor. If the voluminal air flow is measured, one from of deduced the volumic temperature and air flow starting from the pressure raised during the test. This test can be performed on a engine test bench but DinaMotors has Designed Indevidual test bench to have more repeatable measurement save cost and time.

.

Thermal Shock Tests

Thermal shock tests are experiments conducted on an engine installed on a dyno, which aim to assess the influence of extreme temperatures on exhaust system components, as well as assessing wear and thermal deformations.

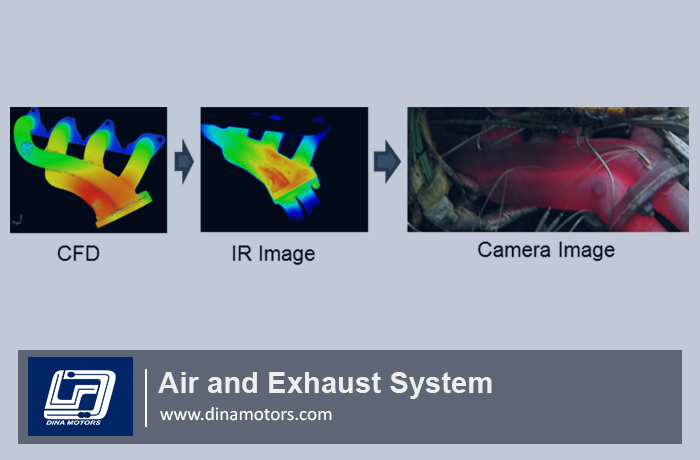

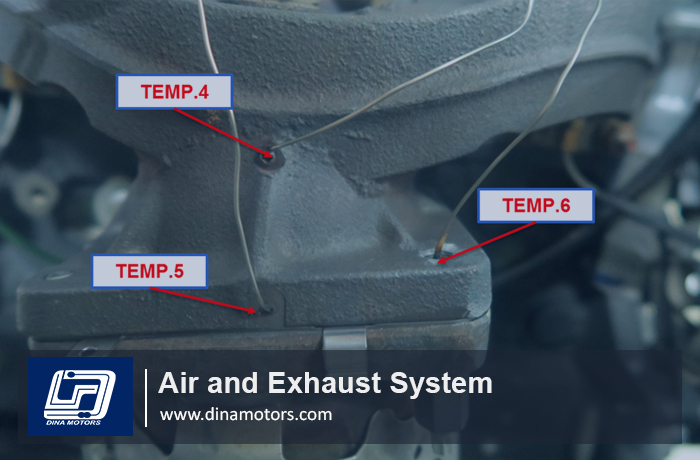

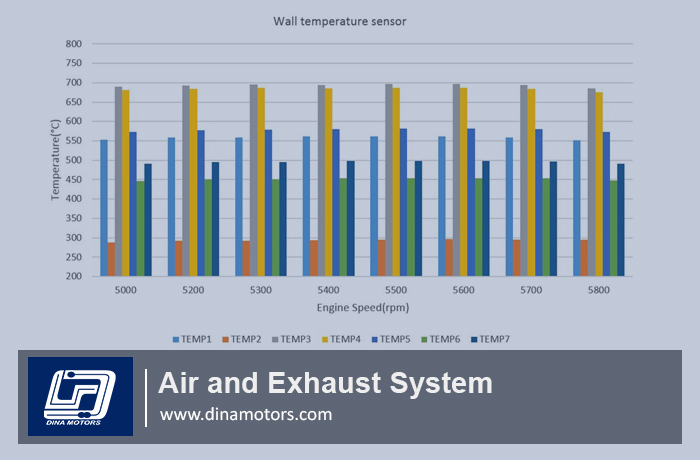

During such tests, temperature of specified points will be measured through 500 hundred thermal cycles in different Engine speed and engine loads. For better analysis we monitor component’s temperature using IR camera and gun.

We also provide CFD services to present solution for better performance.

Mechanical losses tests are conducted on the dyno, where the measurement of torque needed for a combustion engine running under set conditions is possible. The aim of the test is to define the influence of the engine oil in use on the engine’s mechanical efficiency and the reduction of frictional losses. The choice of engine oil also influences the engine’s fuel consumption – and thereby CO2 emissions. The results permit improvement of the lubricating properties of engine oils through quantifying the influence of individual oil additives on the friction within the engine.

.

Tests of fuel dilution of engine oil and the resulting influence on wear of individual engine components are conducted on the engine dyno. In modern Diesel engines, such dilution phenomena most often occur due to frequent particle filter (DPF) regenerations. During testing, through control of the number of DPF filter regenerations, a designated value of fuel concentration in engine oil is maintained, which allows evaluation of the negative influence of phenomena linked to fuel dilution of engine oil on engine components. During tests, oil samples are subjected to regular chemical analyses in order to determine the level of dilution as well as the content of metallic elements.

.

Excessive solubility of air in the oil reduces the oil film in the bearings and causes serious damage to them. This will decrease engine life time and will Leads to financial losses, which is why producing the right oil is so important. In Dina Motors we measure amount of oil aeration using precise equipment.

.

Comparative tests of the “benchmarking” type are conducted on the engine dyno in order to determine the influence fuel and engine oil produced by different manufacturers on engine parameters. During the test, comparative analyses are conducted based on data such as: engine performance, exhaust emissions, fuel consumption, engine subassembly wear and other defined factors. This type of testing allows evaluation of products available on the market and the selection of fuels or engine oils meeting client requirements.

.

Tests determining an oil’s propensity to form sediments on mechanical parts of the engine, for example, the compressor housing or its influence on the wear of lubricated elements, for example the camshaft or the driveshaft. Oxidation, sludge and varnish lead to an increase in viscosity which increases viscosity, friction and wear. Elements tested can be weighed (weight gained – sediments formed; or weight lost – material wear), subjected to both visual analyses and meteorological measurements, before and after the test.

.

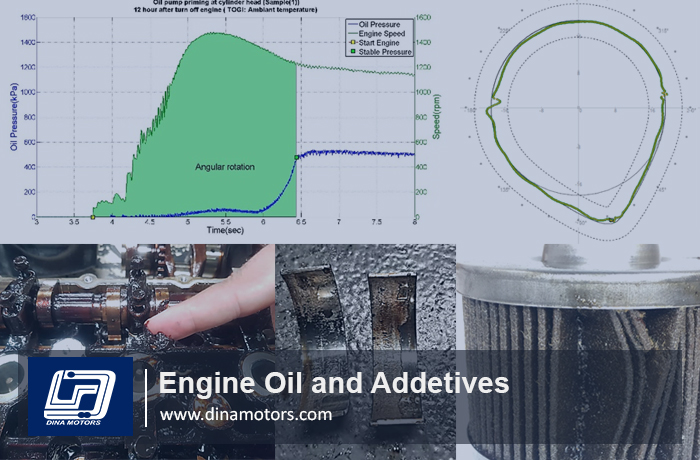

Oil validation tests, for example, durability tests (test duration approx. 1000 h), cold start, efficiency of the lubricating system, allow all engine components whose durability is influenced by the engine oil to be tested. For modern turbocharged engines, often oil validation tests are performed by determining the quantity of sediments formed on the compressor housing and their influence on engine parameters. Requirements of oil characteristics are the temperature rise of the boost air and sediment formation on the compressor. Sediments on the compressor heavily influence its efficiency and durability, both raising the temperature of the boost air and lowering the efficiency of the entire engine.

Many modern production automobile engines use a timing belt to synchronize crankshaft and camshaft rotation and use a Accessory belt to drive multiple peripheral devices in an automotive engine, such as an alternator, power steering pump, water pump, air conditioning compressor, air pump, etc. These belts may also be guided by an idler pulley and/or a belt tensioner (which may be spring-loaded, hydraulic, or manual). The drawback of using belt is that if the belt breaks or is knocked loose, the vehicle instantly loses multiple critical functions. The water pump, power steering pump, and alternator (for battery charging) would cease functioning. The vehicle becomes quickly unusable because of loss of movement in camshafts. Due to importance of belt functions, we monitor acyclisme in pulleys, belt slippage, force and tensioner vibrations at different engine working conditions. Also we qualify belt’s performance through it’s lifespan by running Accelerated life testing on engine at critical belt vibration points for more than 400 hours. During this test mass of tensioner, mass, length and Stiffness of belt will be measured at pre-specified hours. Here are summery of measured parameters:

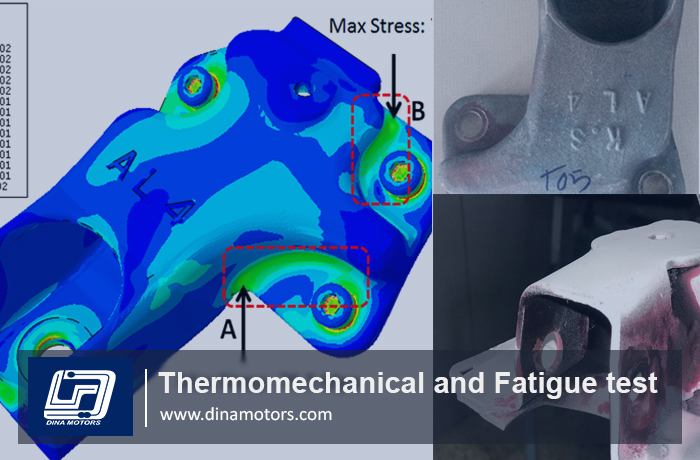

Examples of failure are almost everywhere. Whether it is a minor maintenance failure or a disaster of national significance, anyone can learn from analyzing mistakes. But it’s better to analyze at test rather than service to save cost, time or maybe lives. In Dina Motors Laboratory we perform:

Except checking the results we Inspect for any failure or fracture carefully to inform.

We perform measurements of engine noise and vibrations and the engine dyno. We have performed several dozen such measurements at various locations on the engine: both on the block, sub-systems, turbine and exhaust. We always measure the engine speed at the same time, which is necessary, for example, for Order analysis. If this is not enough, we can also precisely determine the acoustic power of the engine at constant

speeds using an intensity probe. Measurement results can be elaborated in the form of various graphs, but we can also provide raw data as .uff, .txt, .wav files, and in other formats.

.

.

Vibrations and mechanical shocks are generated by an electrodynamic inductor allowing Performing Resistance to sinusoidal vibration, random and mechanical shock tests on the vertical or horizontal axes.

The climatic chamber is integrated into the vibration test bench, which permits production of the required temperature/climatic condition during vibration tests.

We provide the appropriate power supply; electric load, media circuits (air, cooling liquids, etc.) depending on the required installation conditions of the object under test.

We have one- or three-axis accelerometers with a wide range of sensitivities (selected depending on required usage); the vibration system has 6 input channels allowing multichannel vibration control to be conducted and measurement of the test component’s response. We also have great experience in designing and producing vibration brackets.

Dina Motors conducts various types of vibration tests. Elements tested include:

.

.

Modal analysis allows determination of dynamic parameters of mechanical systems, such as:

Modal analysis is not only a good tool for solving problems connected to resonance, but also it plays a great role in product quality control:

A system can be stimulated using different types of excitation: