Engine oil is an important parameter of the engine and its defective performance can cause irreparable damage and breakdown of all moving parts in the engine.

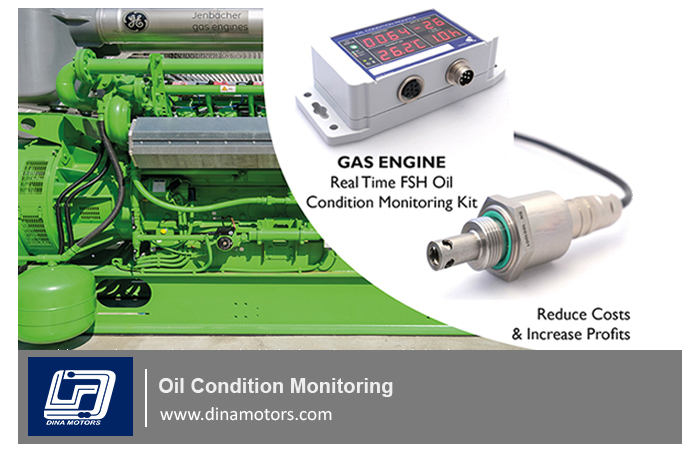

This day, Oil analysis method is one of the effective methods of “condition monitoring” which is used to control important parts of machines such as engines, gearboxes, hydraulic systems and in general the parts where oil is used as a lubricant.

This method has a high efficiency, especially for machinery such as heavy road vehicles, marine vehicles is an effective method.

In fact, in the oil analysis method, the lubricant is used as a rich source of information.

Oil circulation inside the system makes it possible to transfer the effects of events or changes in the system to outside the system.

We have an extensive database of oil analysis, receiving information from more than 2,000 oil analysis reports on various types of compression and spark ignition engines.

The Oil analysis system has the ability to identify healthy engines, suspected of malfunctioning, in need of repair and critical.

This leads to quick maintenance in the field of maintenance, which can be effective in reducing repair time and costs. Studies show that using this method can save up to 70% of engine maintenance costs and reduce storage of spare parts in warehouses.